SCHEDULE : 16 – 27 September 2019

FEE : RP. 18.500.000,- (Include Akomodasi)

VENUE : Lynn Hotel by Horison

(Jogokaryan, Yogyakarta)

[button link=”https://api.whatsapp.com/send?phone=628111788615&text=Hallo%20Admin,%20Daftarkan saya untuk mengikuti training NDT ECT,Weld Inspection” type=”icon” icon=”mail”] DAFTAR[/button]

=====================================================================================

TRAINING OBJECTIVES :

This course meets the training syllabus requirements of ASNT SNT-TC-1A to provide a thorough grounding in the principles of eddy current testing and the fundamentals of engineering, materials and components inspection, such that the technician will be able to :

- identify the suitability of eddy current testing for all materials and inspection applications

- provide analysis of inspection data and documenting the results

- be familiar with regulatory codes and specifications for eddy current testing and its intent

COURSE OUTLINES:

1. Fundamental Theory

- Basic fundamentals of electricity

- Relationship of resistivity to electrical resistance

- Relationship of material resistivity to material conductivity

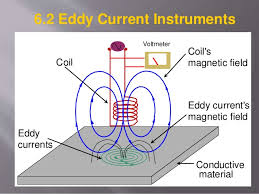

- Electromagnetic induction; self inductance and mutual inductance

- Inductance of eddy current coils

- Generation of eddy currents

2. Advanced Theory

- Fundamental properties of eddy current flow

- Depth of penetration in finite thickness samples

- Phase lag in finite thickness samples

- Simplified impedance diagrams

- Correlation between coil impedance and sample properties

3. Instrumentation

- Bridge circuits

- Typical bridge circuits in eddy current instruments

- Principle operation of eddy current instruments – general purpose instrument (impedance method) – crack detectors – material sorting and conductivity instruments – send & receive of eddy current systems – multifrequency equipment – pulsed eddy current equipment – recording equipment

4. Testing with Surface Probes

- Probe types Probe designs

- Probe inductance and coil design characteristics

- Parameters affecting sensitivity to defects Impedance graph displays

- Characteristic parameters

- Definition of “phase” terminology

- Selection of test frequency for: – inspecting for defects – measuring resistivity & measuring thickness – measuring thickness of a non-conducting layer on a conductor – measuring thickness of a conducting layer on a conductor

5. Surface Probe Signal Analysis

- Eddy current signal characteristics

- Defect signal phase

- Effect of material variations and defects in a finite thickness

- Coil impedance changes with defects

- Coil impedance changes with: – ferromagnetic anomalies – electrical resistivity – surface geometry

- Calibration standards and signals from calibration defects

6. Codes and Specifications

- Interpretation of codes and specifications commonly used

- Report writing

=====================================================================================

Pendaftaran :

Phone : 0254 – 8481815

Email : admin@slv.co.id

Mobile : +62 87771200615 (Bapak Helman)

+62 81210071232 (Admin SLV)

persyaratannya apa saja

Kirimkan CV ke : admin@slv.co.id

Saya blm punya ET level 1.. tapi secara teori sudah cukup pahamsy jg mengajar NDT di institusi pndidikan.. saya ada UT dan RT level 2.. apakah bs langsung ambil Level 2 ET?

Fast track #registration by email ke : admin@slv.co.id

#Kirim CV dan no WA untuk data peserta.

Saya blm punya ET level 1.. tapi secara teori sudah cukup pahamsy jg mengajar NDT di institusi pndidikan.. saya ada UT dan RT level 2.. apakah bs langsung ambil Level 2 ET?